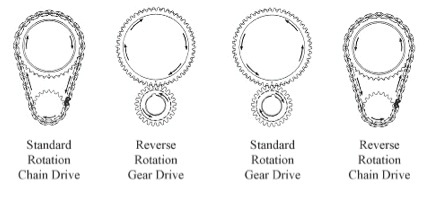

Standard and Reverse Rotation Marine Engines – What to Look For

Boats with twin engines usually turn in opposite direction so the torque reactions of the engines cancel each other out. The following four drawings show how the crankshaft and camshaft turn in the four combinations of drives. Some of the parts in these engines may be interchangeable, but will not function properly and can create problems for rebuilders.

Crankshaft – Some of the reverse rotation cranks have the oil holes drilled symmetrically opposite. Check this closely.

Camshaft – In the above combinations none of the cams are interchangeable. The lobe timing and/or the distributor drive gear angle are different.

Distributor/Oil Pump – In all of the applications, we know of both the distributor and oil pump turn the same direction regardless of the crank rotation. This is done by making the angle of the drive gear on the cam and its mating gear opposite, when the cam turns the opposite direction. This makes the thrust of the gears in the opposite direction. For example, the SE Chevy thrust is up and is taken by the base of the distributor housing and the drive gear.

If the cam rotation and gear angle are changed, the thrust is down and there are no provisions for this in a stock distributor. A ball bearing distributor or magneto is required.

When working on marine engines, be sure you know what the components intended usage is and do not vary from it.