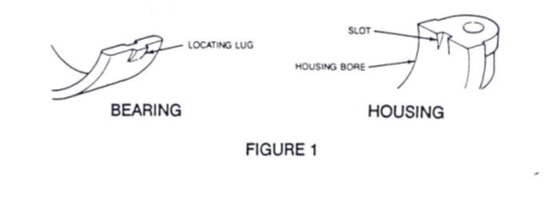

We left off talking about bearing and bushing retention and the terms “Crush” and “Press Fit”. The locating lug on a half shell bearing registers with a mating slot in the housing to locate the bearing shell (figure 1). The lug is not intended to prevent bearing rotation. Crush holds the bearings in place and prevents spinning just as press fit holds bushings in place which have no locating lugs. Each ½ shell bearing has about .004” or so of crush. That is to say: each shell is slightly bigger than ½ circle. When the two halves are assembled and caps tightened to spec, the extra material (crush) creates radial force against the housing bore, holding the bearings in place and insuring good heat transfer.

Lugs can be positioned differently on upper and lower halves or varied in width to prevent misassembly. A number of late-model engines have even eliminated the location lug completely. Regardless of lug or no lug, proper positioning of a crankshaft bearing is essential to ensure oil hole alignment with the housing and to prevent interference between the edge of the bearing and the crankshaft fillet radius.

Some confusion has arisen over the “Lug-No Lug” bearing issue. For engines like the 6.7L Ford diesel, it is quite simple. Every 6.7L diesel engine ever built by Ford has both main and rod bearings with no locating lug so supplying an aftermarket set from Clevite is very simple: no lugs! Where it becomes confusing is an engine family like the 4.7L Chrysler V-8. Chrysler made a production change during the life of the 4.7L going from a lugged design on the bearings to a non-lugged design. Clevite, as did most bearing suppliers, elected to supersede the lugged design to the non-lugged design. The non-lugged part will work in the earlier designs but of course the reverse is not true.

Positioning the non-lugged bearings requires a bit of care so the edge of the bearing shell does not interfere with the radii on the crank. Once you have the shell positioned, free-spread provides the good fit that holds the bearing in that position while you assemble the engine.

Finally, just in case you are wondering about the removal of location lugs by engine manufacturers, it is simple economics. Take a popular example like the 6.7L Ford. The engine has 5 main bearings and 8 conrod bearings. Eliminating the lug pockets in the block and main caps reduces by 10, the machining cuts made at the factory. Add another 16 cuts eliminated on the conrods and you can see, just the savings in tool bits would be substantial, not to mention operator time and machine time savings as well.